Procurement KPIs: 10 Essential metrics for B2B Purchasing

- Arnaud

- 10 minute read

Agility and resilience have become top priorities for the procurement function, now playing a major strategic role. Measuring procurement performance is no longer just a reporting tool: it’s a driver for steering, risk mitigation, and value creation. For procurement professionals, mastering key performance indicators (KPIs) is essential. With the right procurement solution, they not only help evaluate process efficiency but also guide decision-making aligned with the company’s strategic objectives.

1. Why are Procurement KPIs indispensable?

Procurement KPIs are management tools used to measure, analyze, and improve the performance of procurement activities. They provide a clear view of process efficiency, supplier relationship quality, risk management, and achievement of economic objectives.

In an environment marked by price instability, margin pressure, responsible sourcing needs, and accelerated digitalization, tracking the right procurement KPIs is crucial to make fast decisions, prioritize actions, and demonstrate procurement’s contribution to overall performance.

2. Top 10 Procurement KPIs to track in 2026

Here’s a selection of the most relevant procurement KPIs to monitor and steer from your procurement solution:

- On-Time Delivery Rate (OTD)

Measures suppliers’ ability to deliver products or services within the expected deadlines and under contractual terms. A high OTD reflects a reliable and high-performing supplier base. It helps minimize supply chain disruptions and hidden costs (non-conformities, returns, penalties…). - Procurement Compliance Rate (PCR)

Tracks the percentage of purchases that comply with internal procurement policies, established processes, or existing contracts. Why is it important? To manage legal risks, control spending, and encourage adoption of procurement tools (e-procurement, e-sourcing…). - Inventory Turnover Rate (ITR)

A critical logistics KPI, reflecting your ability to optimize stock levels, avoid overstock and shortages, and improve cash flow. Use this in combination with TCO to balance purchase volume, inventory cost, and stockout risk. - Cost Savings Achieved (CSA)

Measures savings generated through renegotiation, supplier consolidation, supplier innovation, or standardization. This KPI was a priority for 77% of procurement departments in 2024 (CNA – AgileBuyer study).

- Supplier Defect Rate (SDR)

Assesses the rate of non-compliance, returns, or defects from suppliers. It helps identify which suppliers need support or reassessment. Integrate this KPI within a structured Supplier Relationship Management (SRM) approach to go beyond basic quality control. - Total Cost of Ownership (TCO)

Calculates the full lifecycle cost of a purchase—from acquisition to maintenance, operation, and disposal/recycling. The goal? Encourage a long-term, value-driven approach, instead of focusing on unit price only.

- Supplier Contract Compliance Rate

Measures the supplier’s adherence to contract terms: SLAs, penalties, sustainability (CSR) commitments, quality clauses, etc.

- Savings vs Objectives

Compares actual savings achieved to initial budget targets. This KPI helps align procurement with financial goals and refine strategies using SMART objectives shared with finance.

- Procurement Process Adoption Rate

Monitors employee compliance with procurement workflows and tool usage. It serves as a barometer of best practice adoption within your organization.

- Supplier Performance Score

A global performance indicator that can combine metrics like OTD, SDR, and contract compliance, often visualized in procurement dashboards or SRM platforms.

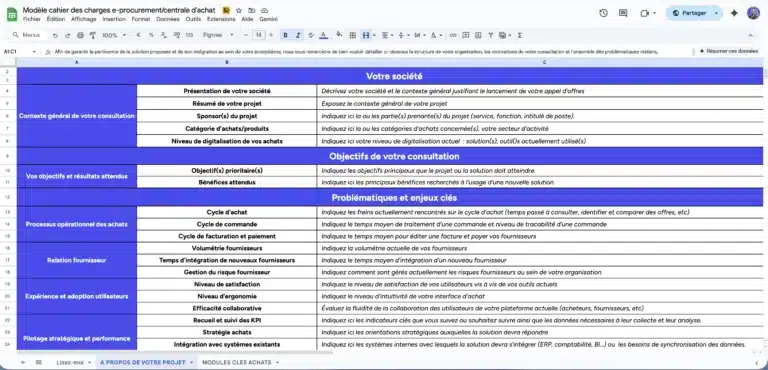

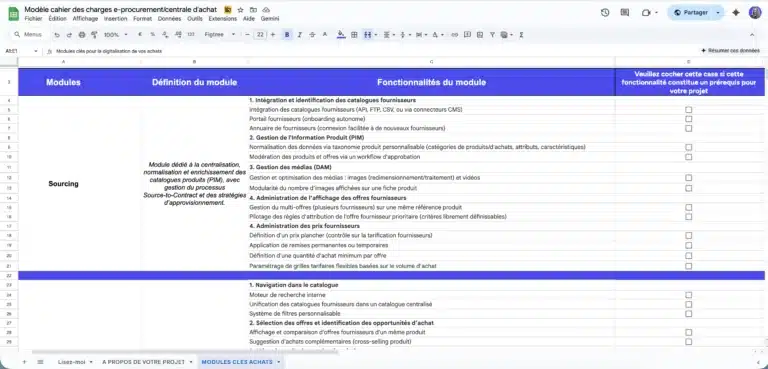

Don’t miss anything in your S2P RFP.

A ready-to-use Excel template to structure your eProcurement / S2P RFP, align stakeholders, and objectively compare vendors.

Excel format • Ready to customize • Built for real-world sourcing teams

3. How to implement relevant Procurement KPIs?

1. Strategic analysis of procurement objectives

Before choosing KPIs, clarify your procurement roadmap:

- Cost reduction?

- Supply chain resilience?

- Sustainable sourcing?

- Supplier innovation?

This ensures that the KPIs are aligned with actual company goals.

2. Selection of aligned and actionable indicators

Avoid trying to “measure everything.” A good procurement KPI should be:

- Specific to a goal

- Measurable with accuracy

- Achievable and actionable

- Relevant to your context

- Time-bound

3. Integration into a dynamic procurement dashboard

An effective dashboard lets you track KPIs in real time, detect trends, and make fast decisions. It must:

- Be visual and easy to interpret

- Include filters by category, BU, or supplier

- Be automated via an IT tool (ERP, Power BI, procurement platform…)

4. Use of data for decision-making and continuous improvement

KPIs are only useful if they support strategic thinking. Analyze deviations, identify root causes, and adjust action plans. For example, a drop in OTD might reveal planning issues or an over-reliance on a single supplier.

4. Procurement KPIs as strategic steering tools

Procurement is no longer just about negotiating prices. It actively contributes to corporate performance, operational resilience, and ESG goals. That’s why steering through KPIs is essential. A good procurement KPI doesn’t just measure it guides, alerts, and aligns. By selecting the right KPIs, tracking them over time, and using them to drive decisions, procurement leaders can turn challenges into competitive advantages.

Want to go further in mastering procurement KPIs or challenge your current strategy? Our experts offer a free diagnostic. Let’s explore how Origami Marketplace can become a performance lever for your procurement.

The article in 1 minute 🕐

The procurement function is a strategic lever for companies. Procurement KPIs are no longer just for reporting: they are used to steer performance, reduce risk, and create value.

- 🔍 Why are they indispensable? They provide clear visibility on process efficiency, supplier performance, and cost control in a rapidly changing environment.

- 📊 Top 10 KPIs to track in 2026: On-time delivery, procurement compliance, inventory turnover, cost savings, supplier quality, TCO, contract performance, savings vs objectives, and adoption of procurement procedures.

- 🛠️ How to implement them well? By defining clear goals, selecting aligned and actionable KPIs, building a dynamic dashboard, and using data for continuous improvement.

- 🎯 Strategic steering via KPIs: Procurement becomes a driver of global impact (financial, operational, ESG). The right indicators lead to better decisions, anticipation, and results.

👉 Need a turnkey solution? Partner with a specialist provider like Origami Marketplace to accelerate your project. Discover how our API and partner network can transform your business, regardless of its size, with its innovative marketplace-based solution.