Why Procurement Digitalization Reduces Total Cost of Ownership?

- Arnaud

- 10-minute read

Facing growing economic pressure, the digitalization of procurement is no longer an option but a strategic necessity. This article demonstrates how a digital approach can significantly reduce the Total Cost of Ownership (TCO), going far beyond the simple purchase price.

With cost reduction becoming the #1 priority for 77% of procurement departments in 2024, digital solutions offer concrete answers: e-procurement, for example, can generate 5-10% in savings, and AI can deliver up to 15% on average. At the heart of this transformation, the marketplace model is proving to be a revolutionary tool, capable of rationalizing spend and streamlining processes with a rapid return on investment.

Beyond financial gains, this digitalization is driving a profound transformation of the buyer’s role. Freed from operational tasks, the buyer is becoming a strategic partner, a data expert, and an architect of the supplier relationship, creating sustainable value for the entire company.

- The strategic imperative of procurement digitalization

- Understanding TCO: Beyond the purchase price

- How digitalization transforms each component of TCO

- The human transformation: The augmented buyer powered by data and AI

- Key technologies in procurement digitalization

- The internal marketplace: Revolutionizing the procurement model

- Measuring the ROI of procurement digitalization

- Implementation: Strategies and best practices

- Challenges and future outlook

- Toward an augmented procurement function

1. The strategic imperative of procurement digitalization

In an economy marked by inflation and market volatility, companies are under more pressure than ever to optimize their spending to remain competitive. At the core of this quest for efficiency, the procurement function emerges as a major strategic lever. Far from being limited to simple price negotiation, it is now called upon to orchestrate a profound transformation—the digitalization of procurement—with a clear objective: reducing the Total Cost of Ownership (TCO).

Procurement digitalization is the integration of digital technologies across the entire procurement process, from need identification to supplier management, ordering, and payment. This approach goes well beyond simple automation; it aims to create a more agile, transparent, and high-performing procurement ecosystem.

TCO, or Total Cost of Ownership, is a holistic approach that encompasses all direct and indirect costs associated with a good or service throughout its lifecycle. It’s no longer just about the initial purchase price, but about all expenses incurred from acquisition to the end of the product or service’s life. Digitalization provides powerful tools to analyze, control, and reduce these hidden costs, thereby transforming the procurement function into a true profit center.

Indeed in France, 79% of SME leaders believe that digital technology represents a real benefit for their company, and 42% consider it a way to generate profit.

In the following sections, we will explore how digitalization impacts each component of TCO, what the key technologies are, and how innovative solutions like the marketplace model can revolutionize your procurement approach.

Alexandre Duquenoy

2. Understanding TCO: Beyond the purchase price

Traditionally, TCO is broken down into four main categories:

- Acquisition costs: These include the purchase price as well as sourcing costs (supplier research and qualification), negotiation costs, administrative costs related to placing an order, and transport and customs fees.

- Ownership costs: This includes storage fees, insurance costs, taxes, inventory management costs, and costs related to obsolescence or asset depreciation.

- Operating costs: These encompass energy expenses, consumables, maintenance costs (preventive, corrective, predictive), staff training, and costs related to downtime.

- End-of-life costs: These include dismantling, recycling, or disposal fees, as well as costs related to the resale or transfer of the asset. Compliance with environmental regulations can also lead to significant costs.

For procurement departments, TCO analysis is crucial because it promotes a more strategic approach where long-term value takes precedence over short-term gain.

3. How digitalization transforms each component of TCO

Digitalization acts as a catalyst to optimize every phase of an asset’s lifecycle, consequently reducing TCO significantly.

3.1 Reducing acquisition costs

- Procure-to-Pay process automation: Adopting e-procurement solutions automates key steps like purchase requisition creation, RFP management, and invoice processing. According to a survey by the Hackett Group, organizations that have adopted collaboration in their procurement processes have achieved an average 5 % reduction in procurement costs, and those that implemented strategic sourcing have seen reductions around 10 %.

- Better supplier sourcing and negotiation: Digital platforms offer unprecedented visibility into a wide range of suppliers. Access to enriched databases and performance histories allows for negotiating better terms. Artificial intelligence can reduce the time spent on basic tasks by up to 80% and automate up to 75% of procurement tasks.

- Controlling maverick buying: Digitalization centralizes information and enforces compliance rules. E-catalogs and approval workflows ensure that purchases are made from preferred suppliers, putting an end to maverick buying.

3.2 Optimizing ownership costs

- Optimized inventory management: Digitalized inventory management systems enable real-time tracking of stock levels. Automated replenishment prevents costly overstocking and damaging stockouts.

- Improved tracking and traceability: Digitalization provides complete visibility into the order lifecycle. Digital tracking tools (RFID, barcodes) allow for precise monitoring of the location and condition of goods, reducing supplier disputes and costs associated with losses.

3.3 Mastering operating costs

- Predictive maintenance and IoT: Thanks to the Internet of Things (IoT), maintenance is no longer just preventive or corrective, but predictive. Sensors collect data which, when analyzed by AI, can anticipate breakdowns, reduce downtime, and optimize maintenance costs.

- Usage analysis and consumables optimization: Data collected on asset usage helps identify optimization opportunities, such as reducing energy consumption or waste.

3.4 Lowering end-of-Life costs

- Traceability and regulatory compliance: Digital tools ensure complete material traceability, which is crucial for managing recycling effectively and ensuring compliance with environmental regulations, thus avoiding potential penalties.

- Optimizing decommissioning and resale: A better understanding of the product through centralized data facilitates its dismantling and helps identify reusable or resalable parts, turning a cost into a revenue source. The refurbished market is booming, with 55% of European consumers open to buying refurbished smartphones in 2024.

4. The human transformation: The augmented buyer powered by data and AI

The most profound transformation driven by digitalization is not just technological; it is human. By automating repetitive tasks, technology does not replace the buyer—it augments them. It frees them from low-value-added operational tasks, allowing them to position themselves as a true strategic partner within the company.

This evolution is evident in several areas:

- From cost controller to strategic advisor: The buyer is no longer just a gatekeeper of spending. Armed with data analysis tools, they become an internal consultant capable of advising business units on the best procurement strategies, based on a complete TCO analysis, risk assessment, and supplier innovation potential.

- The emergence of new skills: To succeed in this transition, buyers must develop a new set of skills. Hard Skills: Mastery of data analytics tools, understanding of technologies (AI, IoT), and market intelligence become fundamental for making informed decisions. Soft Skills: Communication, cross-departmental collaboration, and Supplier Relationship Management (SRM) become essential for building lasting, value-creating partnerships.

- Enhanced collaboration with business units: Digitalization (especially via internal marketplaces) empowers employees to handle simple purchases autonomously. This allows buyers to focus on strategic initiatives, working upstream and in close collaboration with technical, marketing, or production departments to define needs and build tailored solutions.

5. Key technologies in procurement digitalization

The digital transformation of procurement relies on a set of interconnected technologies.

- E-procurement and E-sourcing: These are the pillars of digitalization. E-procurement covers paperless purchasing processes, from request to invoice. E-sourcing focuses on supplier discovery, RFPs, and reverse auctions. They enable workflow automation, information centralization, and improved compliance.

- Artificial Intelligence (AI) and Robotic Process Automation (RPA): AI and RPA can handle repetitive tasks like data entry or invoice verification. According to Zylio, AI can generate average savings of 15% in procurement. AI also analyzes vast volumes of data to forecast needs, anticipate risks, and recommend the best strategies.

- Analytics and Data-Driven Procurement: This involves using data analysis to make smarter purchasing decisions. Dashboards help visualize spend, evaluate supplier performance, and optimize contracts.

- IoT (Internet of Things) and Predictive Maintenance: As mentioned, IoT plays a growing role in controlling TCO. Connected sensors enable predictive maintenance, reducing breakdowns and extending asset life.

The trap is to stack technologies like AI or analytics in silos. This creates a mosaic of complex tools that frustrate users. My advice: think 'ecosystem' before 'tool.' Aim for a single platform that connects everyone. The marketplace model is exactly that. It's not just another technology; it's the orchestrator that turns your tech stack into a coherent strategy, combining user experience, data, and connection to your entire ecosystem.

Antoine Mantel

6. The internal marketplace: Revolutionizing the procurement model

Beyond traditional tools, the internal marketplace is redefining the procurement landscape. While its most immediate application in a TCO reduction strategy is the internal purchasing marketplace, it’s essential to understand that the marketplace model is much more than a simple procurement tool. It is a versatile multi-supplier platform that creates a seamless and transparent ecosystem, transforming how a company interacts with its employees, suppliers, and even its own customers.

| Feature | Classic ERP Solution | Central Purchasing Body | Marketplace |

|---|---|---|---|

| Supplier Flexibility | Low | Medium | High |

| Employee UX | Low | Medium | Strong |

| Time-to-Market | Slow | Medium | Fast |

| Spend Control | Yes | Yes | Yes + |

| Continuous Innovation | No | Low | Yes |

Optimizing procurement and the employee experience is the starting point and the core of the TCO strategy. Internally, the marketplace acts as an intuitive, private purchasing portal.

- User experience and adoption: By offering a B2C-inspired design, it ensures massive adoption by employees, which is essential for channeling spend and eliminating “maverick buying.”

- Streamlined procure-to-pay process: From product search to invoicing, the process is simplified and accelerated, generating considerable productivity gains for all departments and for procurement teams.

- Control and rationalization: It allows for centralized control of spending by the procurement department while decentralizing the act of purchasing.

The marketplace also radically transforms the supplier relationship. It is no longer just an ordering channel but a platform for collaboration and performance.

- Simplified supplier management: The platform digitalizes and streamlines the entire supplier lifecycle: from onboarding (document collection, qualification) to managing catalogs and pricing.

- Performance and healthy competition: By centralizing orders and interactions, the marketplace collects valuable data on each supplier’s performance (delivery times, product quality via user ratings, etc.). This enables objective and continuous evaluation while creating a healthy competitive environment that encourages them to offer the best service at the best price.

- Enhanced collaboration: The platform becomes a single communication hub, facilitating exchanges, dispute resolution, and collaboration on new offers. The relationship shifts from purely transactional to a true strategic partnership.

Mastering marketplace technology internally opens the door to new, externally-focused strategic opportunities. The expertise gained can be leveraged to create value beyond simple cost reduction.

- B2B sales marketplace: A company can launch its own marketplace to sell its products and services, potentially inviting partners or resellers. This creates a new, powerful, digital, and scalable sales channel.

- Group purchasing organization (GPO): An organization can use this model to create a GPO or service hub for its own customers or members. For example, a professional federation can launch a marketplace offering negotiated services and products to all its members, as the French Tennis Federation has done successfully.

The marketplace is truly a revolution in the procurement model. It starts by optimizing internal processes for a direct impact on TCO, but its strategic potential is much broader. It transforms supplier management into a dynamic partnership and opens the door to new business models. Technological solutions like Origami Marketplace are designed to support this versatility, allowing for the creation of custom platforms for procurement, GPO management, or the launch of complex B2B marketplaces.

Discover how our multi-vendor procurement solution can transform your purchasing process into a strategic lever. Benefit from simplified management, better visibility into your spending, and a quick return on investment.

7. Measuring the ROI of procurement digitalization

To effectively evaluate the return on investment (ROI) of procurement digitalization, a structured and rigorous approach is essential. Here are the key steps to follow:

1. Identify Initial Costs

- Purchase of software and digital tools

- Integration with existing systems

- Team training

- Potential changes to internal processes

2. Quantify Direct Benefits

- Reduction in purchase prices through better negotiation or e-auctions

- Decrease in administrative costs (order processing, invoice management, etc.)

- Reduction in storage costs via better planning and supply management

3. Quantify Indirect Benefits

- Productivity gains for procurement teams and employees

- Improvement in the quality of purchased goods or services

- Reduction of supplier risks

- Better compliance with internal policies and regulations

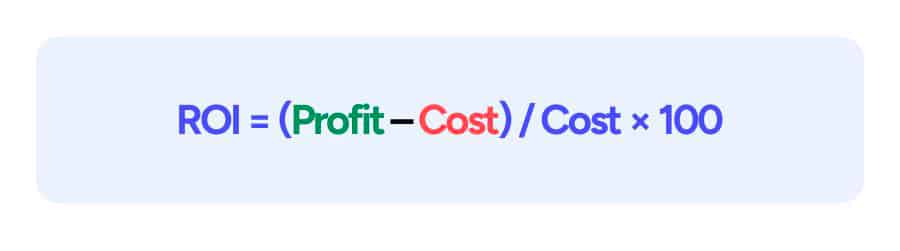

Calculate the ROI

- The classic ROI formula is:

It is important to consider a sufficient analysis period (usually 1 to 3 years) to allow the benefits to fully materialize. By adopting a rigorous ROI measurement approach, procurement departments can justify their investments in digitalization and demonstrate their direct contribution to the company’s financial performance.

8. Implementation: Strategies and best practices

Digitalizing procurement is a major project that requires a structured approach.

Key transformation steps:

- Diagnosis and goal setting: Conduct an audit of existing processes and define clear, measurable objectives.

- Technology selection: Choose suitable tools, prioritizing modular and scalable solutions.

- Phased rollout and pilot: Opt for a gradual approach, starting with a pilot project in a limited scope.

- User training and support: Comprehensive training and ongoing support are essential for adoption.

Change management and pitfalls to avoid:

The human dimension is paramount. It is crucial to communicate transparently and involve all stakeholders. It is also vital to avoid common pitfalls:

- Pitfall #1: Neglecting change management. Resistance to change is a major obstacle. Focusing only on technology without supporting the teams is the primary cause of failure.

- Pitfall #2: Underestimating data quality. Digitalization relies on quality data. Incomplete or outdated data compromises the effectiveness of the tools.

- Pitfall #3: Lack of skills. Mastering new technologies requires specific skills. It is imperative to invest in team training or recruit new talent.

9. Challenges and future outlook

Several challenges can hinder digitalization: resistance to change, the complexity of integrating with existing systems, and data quality and security. Trends for 2025 and beyond promise new revolutions:

- Generative AI: It could revolutionize contract drafting, technical specification creation, and even the generation of negotiation scenarios.

- Blockchain: It could enhance the transparency and security of supply chains by ensuring product authenticity and transaction traceability.

- Responsible and sustainable procurement: Digitalization will facilitate the integration of ESG (Environmental, Social, and Governance) criteria into purchasing decisions.

10. Toward an augmented procurement function

The digitalization of procurement is no longer an option but a strategic necessity for companies aspiring to operational excellence and optimized cost management. By adopting a holistic TCO approach, procurement departments can transform their role from a cost center to a true engine of value and innovation. As we have seen, the marketplace model embodies this new era of procurement. However, the most fundamental transformation is human.

For procurement leaders, it is time to fully embrace this dual revolution of tools and skills. By investing in digitalization, you are not just optimizing processes; you are building an augmented procurement function, capable of anticipating, innovating, and creating sustainable value for your company.

If you would like to discuss this further and see how to proceed, our experts are available to help you imagine this revolution together.

The article's key takeaways in 1 minute! 🕐

Faced with cost pressure, focusing on the purchase price is no longer enough. The solution is to analyze the Total Cost of Ownership (TCO), which includes all hidden costs over a product’s lifecycle: acquisition, ownership, operation, and end-of-life.

Digitalization provides the levers to reduce each of these components. Automation (e-procurement) lowers acquisition costs by 5-10%, predictive maintenance (IoT) reduces operating costs, and better data management optimizes inventory (ownership costs) and recycling (end-of-life costs).

The marketplace model is the culmination of this approach. More than a tool, it’s an ecosystem that simplifies the user experience, streamlines supplier relationships, and offers strategic flexibility. This technological transformation is also human: it elevates the buyer from a mere cost controller to a strategic partner, expert in data and advisory.

This project, with its measurable ROI, is no longer an option. Digitalizing procurement means building an augmented procurement function that creates lasting value for the company.

👉 Need a turnkey solution? Partner with a specialist provider like Origami Marketplace to accelerate your project. Discover how our API and partner network can transform your business, regardless of its size, with its innovative marketplace-based solution.